As the world shifts towards sustainable practices, electric vehicles (EVs) have become a symbol of environmentally conscious transportation. While EVs offer a cleaner alternative to traditional gas-powered cars, questions arise about the environmental impact of their key component: the battery. In this blog post, we’ll delve into the fascinating process of recycling electric vehicle batteries, shedding light on the eco-friendly journey that ensures the responsible disposal and reuse of these vital energy storage units.

Collection and Transportation:

The journey of recycling electric vehicle batteries begins with the collection and transportation of spent batteries. This phase involves setting up collection centers and establishing efficient transportation networks to gather batteries from various sources, including auto manufacturers, dealerships, and end-of-life vehicles.

Sorting and Inspection:

Upon arrival at a recycling facility, the batteries undergo a meticulous sorting process. This step involves categorizing batteries based on type, size, and chemistry. Additionally, a thorough inspection is conducted to identify any potential hazards and assess the overall condition of the batteries. Batteries that pass inspection move on to the next stages of the recycling process.

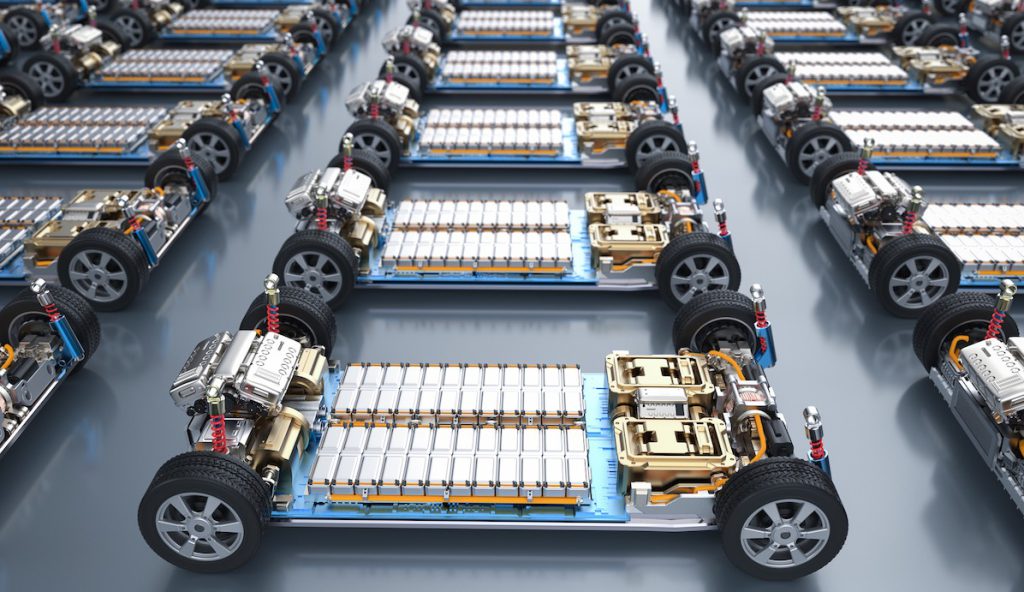

Battery Disassembly:

The disassembly phase involves breaking down the batteries into their individual components. Skilled technicians carefully extract valuable materials, such as lithium, cobalt, nickel, and other metals, which will be reused in the production of new batteries. This step not only conserves precious resources but also reduces the environmental impact of mining for these materials.

Chemical Recovery:

Next, the batteries undergo a chemical recovery process. During this stage, hazardous materials, including electrolytes and other potentially harmful substances, are neutralized and safely disposed of. This ensures that the recycling process adheres to strict environmental standards, preventing the release of harmful chemicals into the air, water, or soil.

Material Refinement:

The recovered materials, particularly metals like lithium and cobalt, undergo a refining process to meet the specifications required for manufacturing new batteries. This step plays a crucial role in maintaining the quality and efficiency of the recycled materials, ensuring they can be seamlessly reintegrated into the production cycle.

New Battery Manufacturing:

The refined materials are then used in the production of new batteries. This closed-loop system maximizes the utilization of resources, reduces the demand for raw materials, and minimizes waste. The recycled materials contribute to the creation of batteries for new electric vehicles, completing the sustainable cycle.

The recycling process of electric vehicle batteries exemplifies a commitment to environmental responsibility in the automotive industry. By carefully dismantling and reusing these vital components, we not only minimize the ecological footprint of electric vehicles but also contribute to the conservation of finite resources. As the demand for electric vehicles continues to rise, the development and optimization of battery recycling technologies play a pivotal role in creating a truly sustainable and circular economy for the automotive sector.